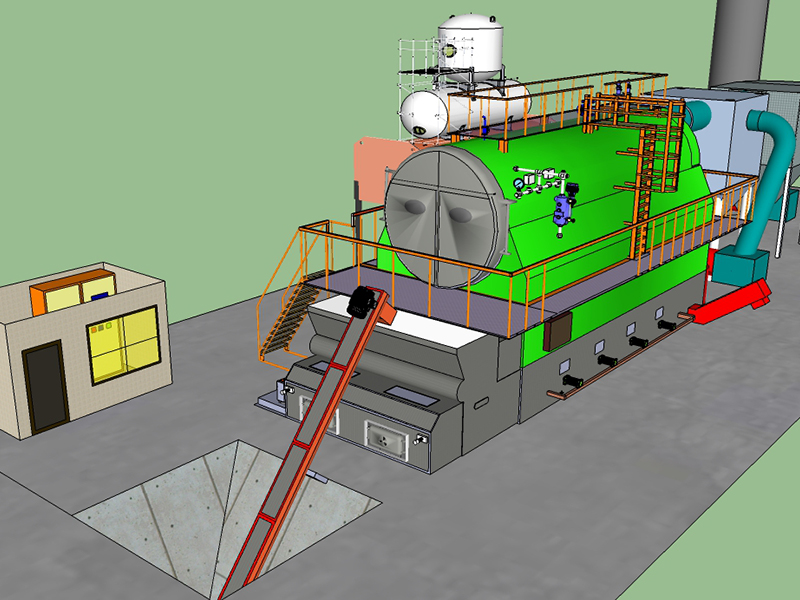

Solid fuel fired boiler consist of two parts, water-tube and fire- tube type boilers in a single united body.

Primary furnace as water- tube (tube+bar) boiler mounted on a rotating grid is manufactured as high enough height to from a large volüme of combustion chamber on the grill.

Scotch type fire-fume tube type boiler and flame radiation type water tube boiler are connected to each other byu means of water collector.

High-volume combusiton chamber is required for burning solid fuels, to keep flame length high and the maximum level of effiency.

Flame-flue type boiler is the two pass type and designed so that the smoke passages appropriate velocity.

Due to the sufficient smoke passage in the boiler very large portion of produced heat remains in the boiler, and used fort he production of steam.

With a large steam volume the boiler can respond to system immediately to withdrawals of peak steam, water tube steam generation by means of primary combustion chamber provides fast steam for flash steam need. Flame- smoke-tube boiler, pipes can be changed easily by means of front and rear doors.

HYBRID BOILER CHARACTERISTICS

Hybrid steam boiler is a composite boiler which is consist of combination of 2 different parts. Water-tube and smoke- tube type boilers as one unit.

Large volüme of combustion chamber is constructed around travelling grid and surrounded by water tube membrane walls.

Scotch type flue-gas tube boiler and radiation heat transfer based water-tube type boiler is combined to each other by means of water and seam headers.

High- volüme combustion chamber, is required to achieve maximum combusiton effiency.

Flue- gas tube type boiler is designed so that two-pass type to achieve maximum capacity and maximum effiency.

Smoke passages are utilized in two different diameters of smoke tubes.

As temperature decreases with decreasing volüme of smoke, gas passes through the boiler tubes at the proper speed through the boiler.

Due to longer flue gas passage ways in the boiler , a very large portion of the heat raised from the fuel burned remains in the boiler and used in production of steam.

Changing of the flue gas tubes can be performed very easily by opening the front and rear doors of the boiler.

SOLID FUEL BURNING SYSTEM WITH TRAVELLING GRATE

It is a conveyor type grate mounted below the primary combustion chamber which is surrounded by water tube membrane walls.

Travelling grate is manufactured with special heat- resistant alloy cast iron material. Chain beans are designed so that; combustion air flows between them, which allows the entire surface of the grate for proper combustion. Burning capacity can be maintained at the desired level by means of plurality of air vents and flaps deemed necessary from the bottom of the grate.

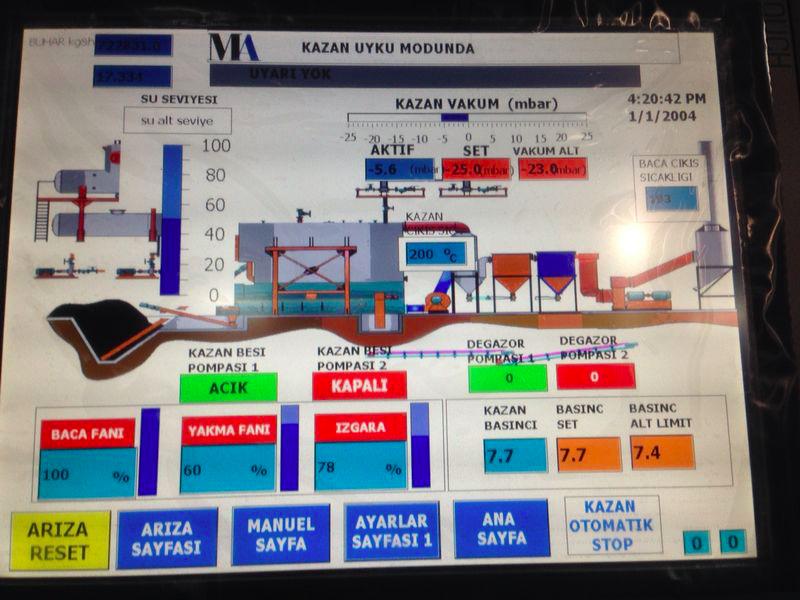

Using the inverter, the speed of the stoker is adjusted according to the effiency of combustion of the coal loaded onto the grate.

Coal begins to burn at the inlet of combustion chamber just after laying on the grate, and continues to burn until the end of the grate in a homogeneous manner.

Travelling grate unit is shipped from our factory as completely assembled. As a seperate unit the boiler is placed onto the conveyor grate with a mobil crane. This process allows for field installation is finished in a very short time.

Boiler and conveyor grate placed on a flat concrete floor allows customers to minimize the cost of construction; this is one of the most important advantages.

Coal to be burned must be of suitable quality as defined regulations by the ministry of environment. Ash, moisture and low-sulfur, high-calorific value coal should be preferred.

The conveyor grate coal burning systems which is the mostly used in the World and is one of the improved design of solid fuel firing systems are used in our steam and thermal oil boilers.

Conveyor grate is manufactured from special alloy heat-resistant cast iron material. Chain links; has been designed so as to allow combustion on the entire surface with thin formed air outlets between them.

Necessary amount of combustion air from the various air channels at the bottom of the grate are being given and the burning capacity can be maintained at the desired level. The rotational speed of the grate is adjustable according to the required combustion efficiency of the coal loaded onto the grate by means of speed adjuster.

Coal is distributed equally and at the desired thickness of layer onto whole grate by means of adjustable coal loading system located behind of the coal loading bunker.

Just after the solid fuel is started to be laid down onto the conveyor grate immediatelybeing exposed to radiation heat and burnable gases starts to be released and that gases starts to burn at the entrance of the grate and coal continues to burn homogenously until end of the grate.

At the end of the grate, since the combustion is completed over, the remaining small amount of ash and slag is poured into the slag bunker and it is taken out from that bin.

In case of steam pressure drop, speed of grate and coal feed grate and coal feed rate is adjusted automaticallyby electronic PLC system which is adjusting speed proportional to steam pressure and boiler reaches to required capacity.

Thus, when the critical pressure is reached applied program keeps the during system at idle capacity without complete interruption. This will minimize energy losses. Primary and secondary combustion air given from both sides of the grate be controlled PLC, so cooling of the grate and combustion of coal on the entire surface of the grate is provided.

Unburned coal parts accumulated in the bin located under and in front of the grate and then sent to the coal bunker again for re-burn thanks to the burn thanks to special design of the reservior sending it automatically to the grate.

All operations starting from loading of the coal into bunkers, burning of the coal and discharge of slag& ash is fully automated by PLC automation system. By that system both high efficient way of combustion and very low emmissions are achieved.[/vc_column_text]